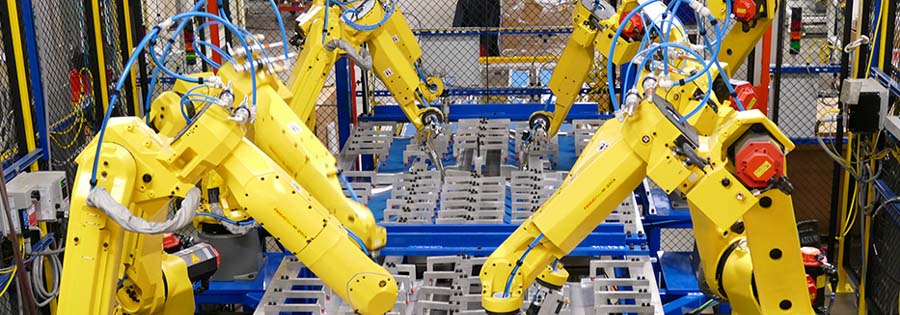

Numerous products necessitate the assembly of diverse components or partial units, either for further incorporation into a larger assembly or to prepare the products for sale. Manufacturers opting to outsource assembly processes can gain substantial advantages by avoiding the in-house execution of these labor-intensive tasks and instead outsourcing to factories with lower labor costs and overhead. Our expansive and adaptable layout in our factories allows us to establish dedicated assembly lines tailored to volume requirements for a broad spectrum of electro-mechanical products and assemblies.