Alphawerk’s Manufacturing Potentials

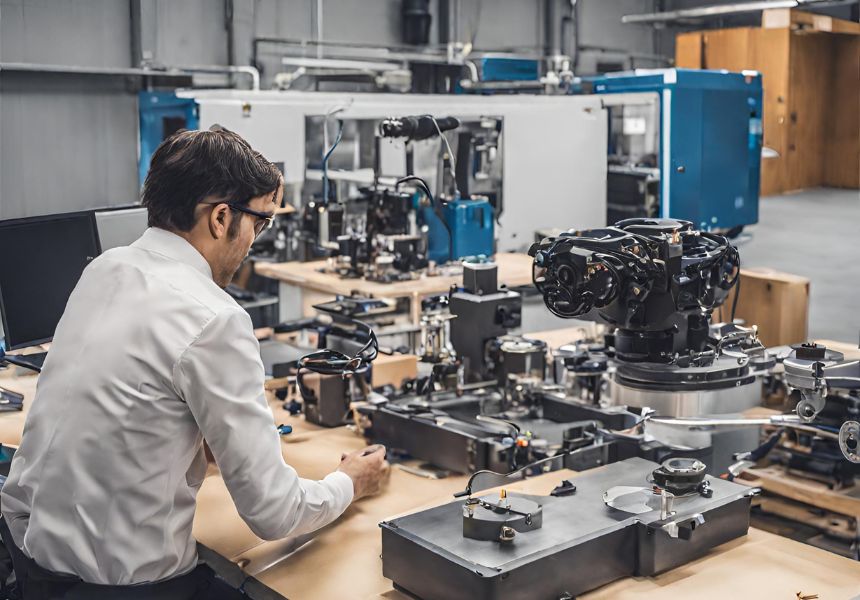

Elevating Manufacturing Excellence, Unleashing a World of Manufacturing Possibilities

Our Potentials

At Alphawerk, we pride ourselves on being your complete one-stop manufacturing solution with virtually unlimited production capacity and a comprehensive range of capabilities. Our precision manufacturing services cover various processes to meet your diverse needs.

Extrusions

High-quality aluminium extrusions with complex cross-sections. Cutting, CNC machining, and surface treatment services.

Die Casting

High-quality die-cast components in materials like aluminium, zinc, copper, brass, and bronze alloys. CNC machining and surface finishes including shot-blasting, texturing, plating, and painting.

CNC Machining

Tight-tolerance components machined from bar stock. Machining of various materials, from soft aluminium and brass to hard titanium and cobalt-chrome alloys.

Forging

Various forging types, including drop forging, hot/cold forging, rolled ring forging, and press forging. Post-processing with precision CNC machining and surface finishing.

Injection Molding

Production of parts in a wide range of sizes and complexity. Post-processing options such as painting and texturing.

Sheet Metal Stamping

Custom sheet metal stampings in materials like cold-rolled steel, stainless steel, brass, and more. Complete secondary operations including powder coating, painting, anodizing, and assembly services.

Prototyping and Pre-Production

Prototyping services with no minimum order quantity. Design and process expertise, with the ability to scale up production quickly.

Investment Casting

Investment cast components in various metals, including carbon steel, low-alloy steel, stainless steel, aluminium, brass, and bronze. Secondary operations like finish machining, heat treatment, and surface treatment.

Assemblies

Dedicated assembly lines for electro-mechanical products and assemblies. Large, flexible layout factories to meet volume requirements.

CAN ALPHAWERK MAKE IT?

If you have a specific manufacturing need not listed here, worry not. Alphawerk boasts virtually unlimited manufacturing capacity and capabilities. Let us know your requirements, and we'll collaborate to ensure you receive the components you need.

Copyright 2023 ALPHAWERK