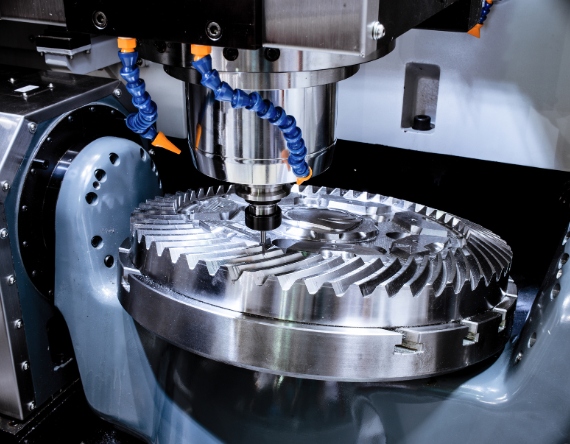

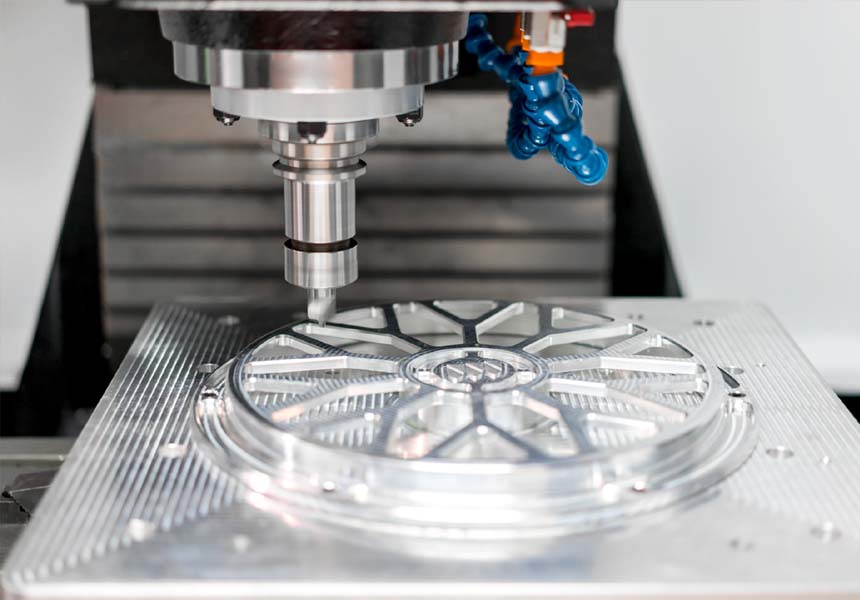

DESIGN FOR MANUFACTURING EXPERTISE

Upon receipt of your purchase order, we will initiate a formal Design for Manufacturability (DFM) review in collaboration with you and your team. This critical step aims to optimize the design, proactively preventing issues, minimizing production time, and ensuring that the investment casted components align with your design and performance criteria.