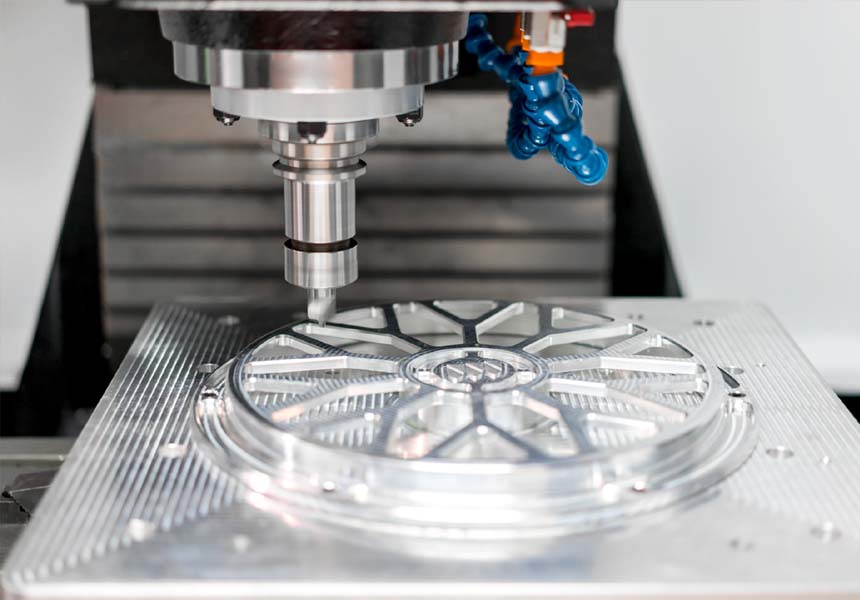

TOOLING DESIGN

Tooling design stands as a crucial optimization step capable of enhancing the efficiency of manufacturing injection molded components. This design process takes into account manufacturing tolerances and factors in typical wear stemming from usage, contributing to improved speed in the production process.